Sustainable process design and optimization

As the concentration of CO2 in the atmosphere continues to increase, global warming is getting severe, and reducing CO2 emissions has become ever more critical. PSSE researches two process systems for increasing sustainability; H2 and CCU process.

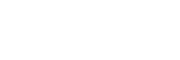

H2 process

H2 process

H2 is a promising agent to replace the conventional fossil fuel-based energy system. To develop H2 economy, PSSE researches H2 importing scenario modeling, H2 supply chain management, and H2 liquefaction process modeling.

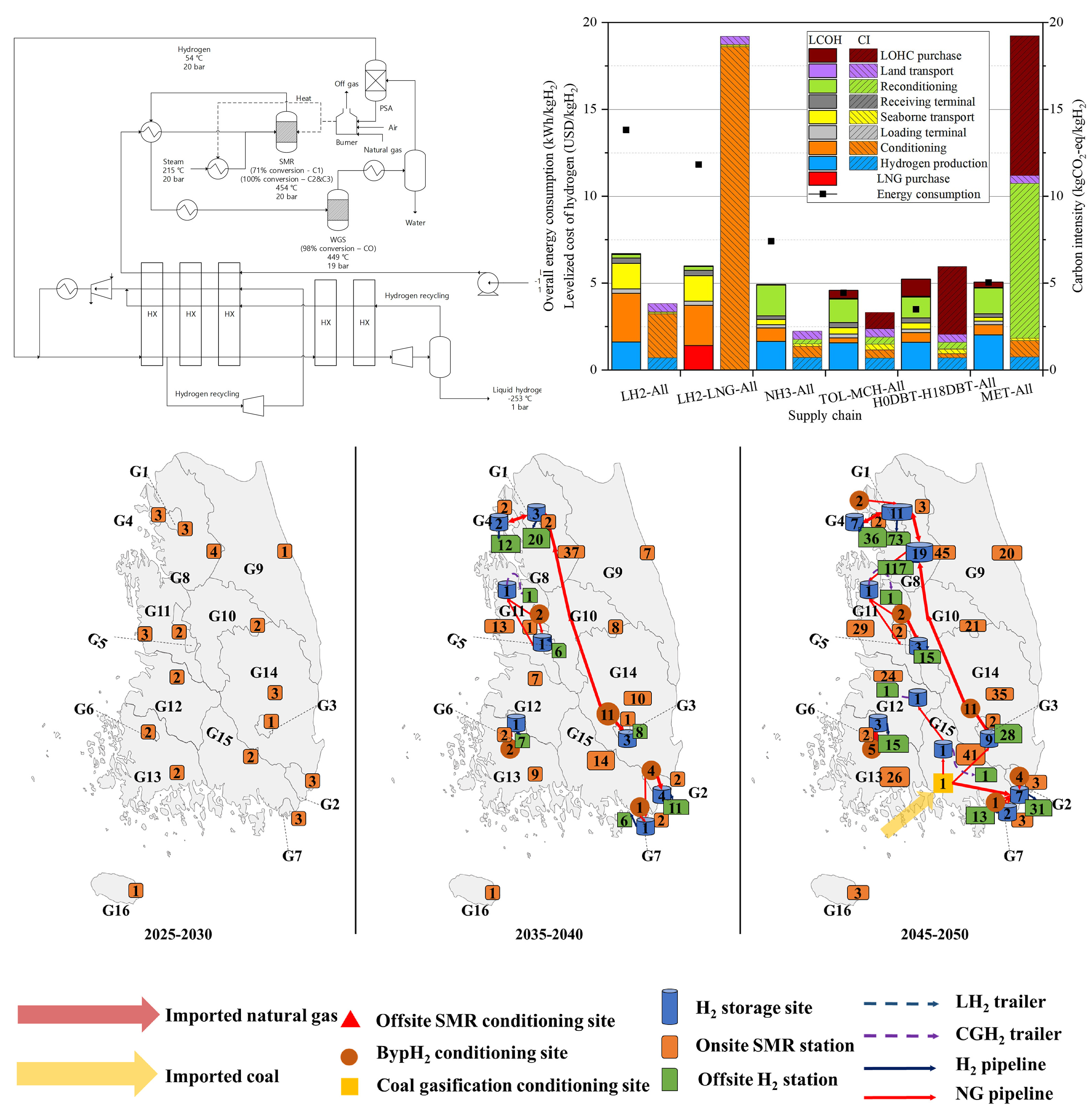

CCU process

CCU process

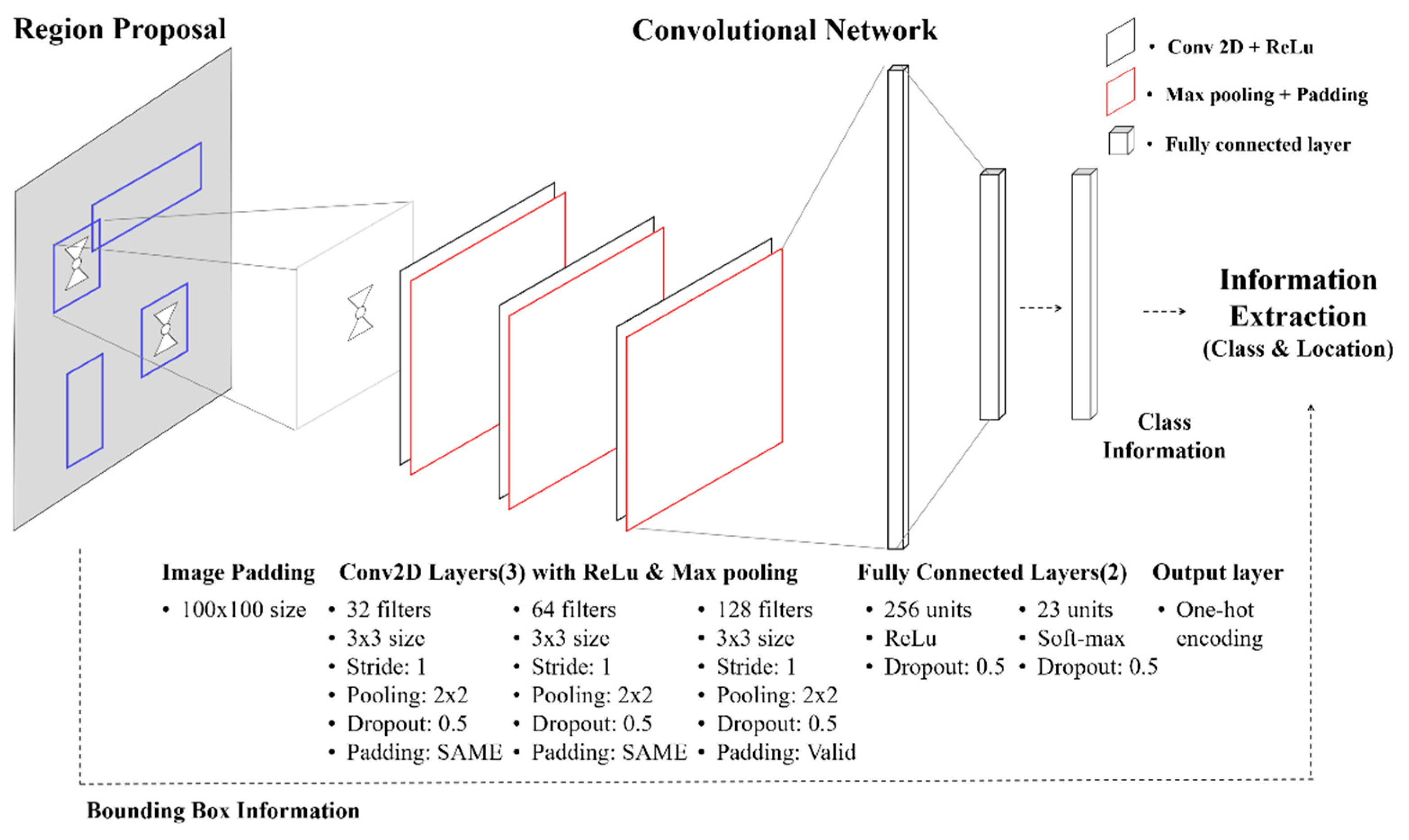

Application of Machine Learning Technologies to Process Systems Engineering

The modern chemical industry challenges more complex and complicated modeling works in chemical reactions, polymer engineering, fluid dynamics, process synthesis, control, and optimization. Machine learning (ML) technologies enable us to reduce the complexity of problems and expensive computational costs. However, the application of ML in different categories of the chemical engineering field requires specialized methods and novel algorithms for each domain of knowledge. To widen the application areas of machine learning technology in the chemical engineering field, we are interested in the development of (1) surrogate models reproducing experiments or simulation results, (2) data-driven models obtained from data mining, operational records, or unstructured data, (3) data-analytics methods using statistical techniques, (4) frameworks solving practical problems, and (5) integration with optimization models.

Relevant Publications

Relevant Publications

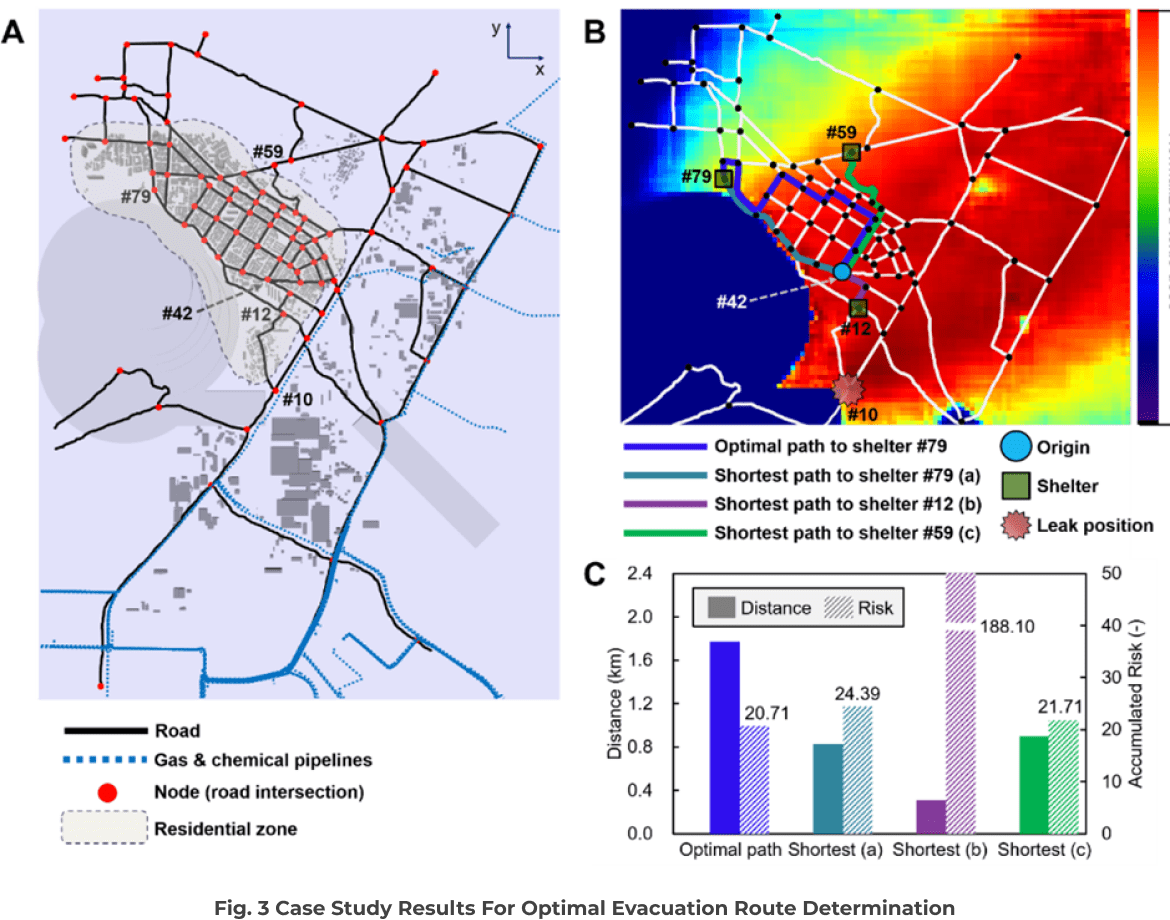

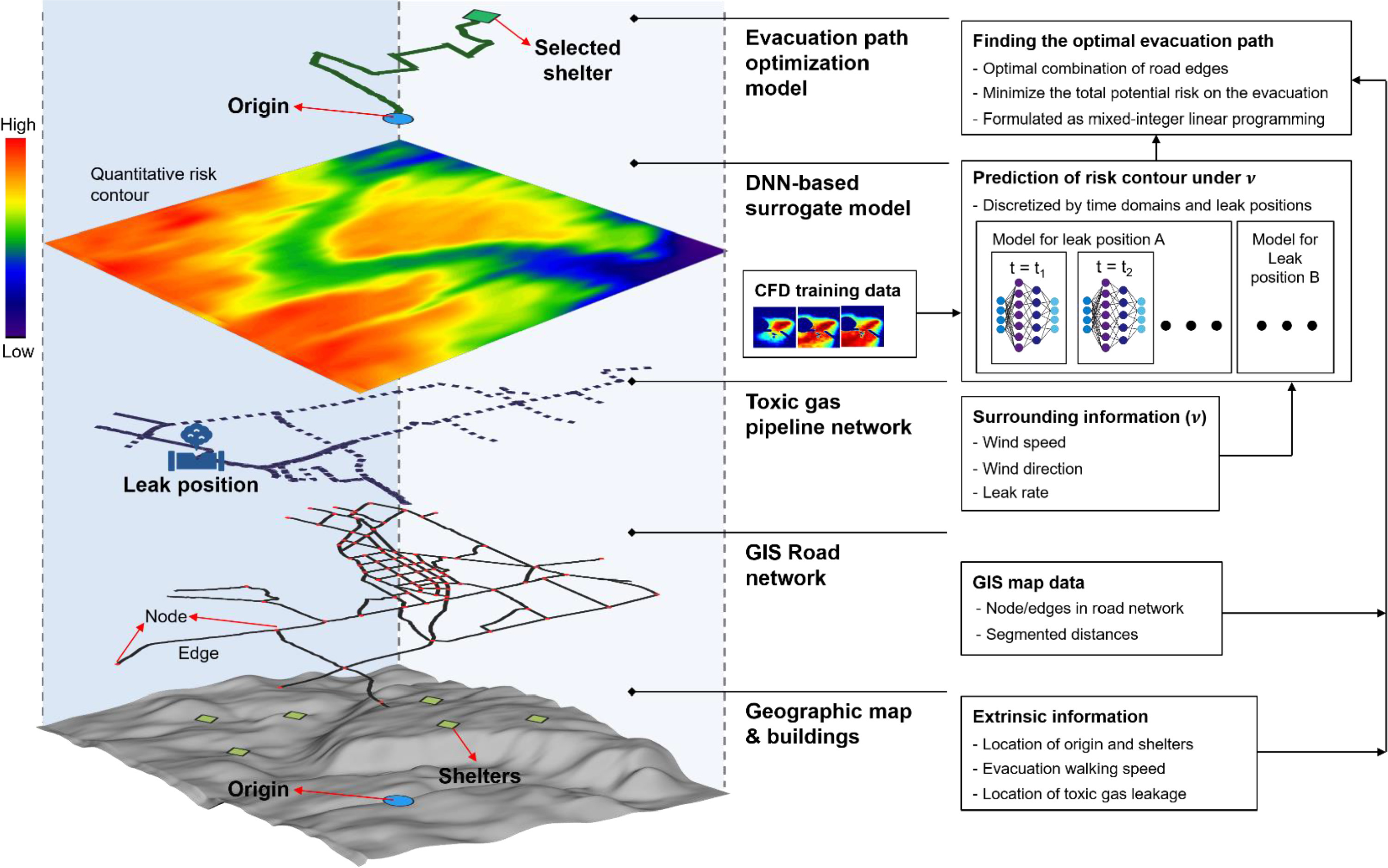

Deep Neural Network-based Optimization Framework for Safety Evacuation Route during Toxic Gas Leak Incidents

Process safety

As part of ESG, which has emerged as a new trend in the industry, it is becoming important to protect workers and surrounding citizens from the risk of chemical process accidents. In addition, consideration of process safety, even to prevent financial losses from accidents, is not an option but a necessity. The main areas of process safety are as follows.

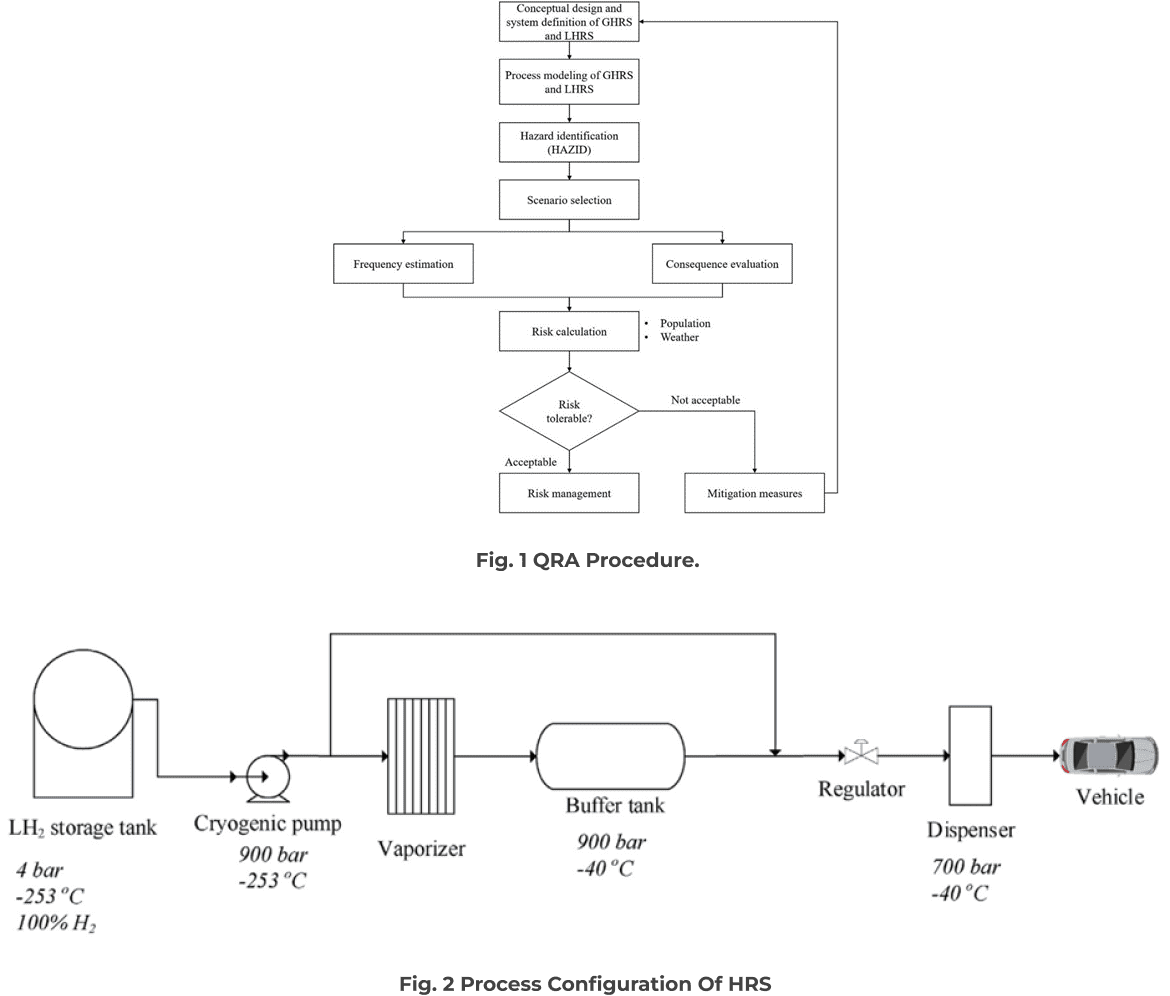

Hydrogen refueling station (HRS)

Hydrogen refueling station (HRS)

Safety must be ensured in order to install a hydrogen charging station operating at high pressure or high temperature in the city center according to the hydrogen storage method; liquid organic hydrogen carriers, ammonia, etc. Currently in the stage of introducing hydrogen infrastructure, it is reasonable to adopt a hydrogen storage method that is economical, environmental, and furthermore guaranteed to be safe. The safety of the process is analyzed by a methodology such as Qualitative Risk Analysis (QRA).

Safety Evacuation